Companies that manufacture, import, export, or rebrand electrical and electronic equipment must ensure their products don’t contain more than a permitted level of hazardous substances. The Restriction of Hazardous Substances Directive (RoHS) directive originated in the European Union. It is meant to restrict the use of specific hazardous materials in electrical and electronic products.

These days, a lot of household appliances and consumer electronics should pass RoHS compliance, owing to the materials used for manufacturing them. EU regulations are made to facilitate trade and promote competition within the 35-nation bloc. And the United States is restricting what local makers of electrical and electronic equipment can include in their products.

How to Know If you are RoHS Compliant

To know if you are compliant, you should first understand the restricted substances and which of your products are in scope. These substances include lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls, polybrominated diphenyl ethers, benzyl butyl phthalate, Bis (2-Ethylhexyl) phthalate, dibutyl phthalate, and diisobutyl phthalate.

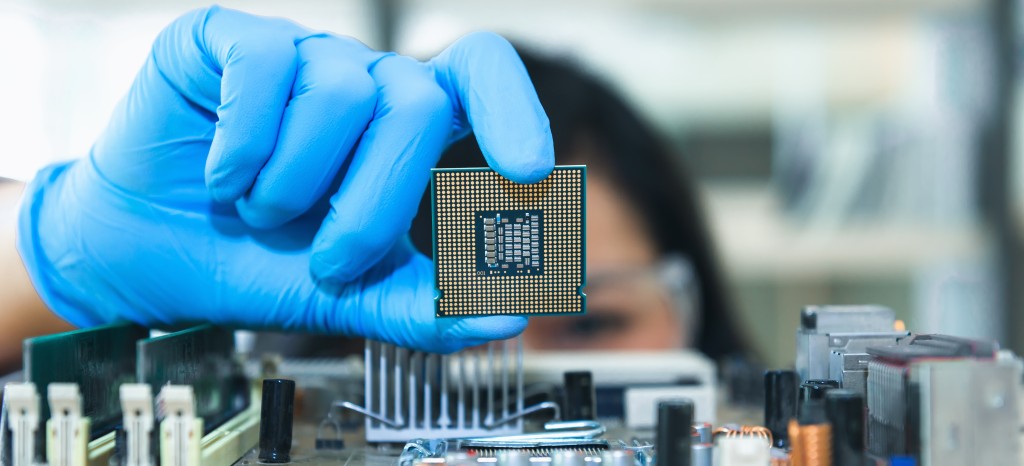

The directive applies to any company manufacturing or importing finished EEE products into the European Union. EEE products are those that depend on electrical currents or electromagnetic fields to function properly. They include those used to generate, transfer, and measure such currents and fields.

Importance of RoHS Testing

Becoming RoHS compliant is important if you want to sell any type of electronic or electrical products on the EU and European Economic Area market. Enviropass RoHS testing ensures you get a RoHS CE mark, which is a mandatory requirement. You need this mark to legally sell your product in the EU. Also, this mark offers consumers and regulators confidence about your product’s safety. The CE mark is also used for showing conformity with other European legislation like the Low Voltage Directive or the Electromagnetic Compatibility Directive.

Testing helps discover issues as well as avoid fines and expensive product recalls. It covers materials, components, parts, and finished products. Providers of RoHS compliance testing services also give advice on relevant regulations to your product and the necessary step to compliance.

Demonstrating RoHS Compliance

To demonstrate RoHS compliance, companies require data from their supply chain because a non-compliant component or part makes the final EEE non-compliant. This makes it necessary to consistently engage with suppliers to get substance information on parts at the homogenous material level. To more easily demonstrate compliance, companies request RoHS compliance certificates from their suppliers for the parts used in the final equipment.