There are so many functions performed by today’s sophisticated, technology driven palletizing systems. Breaking down those functions and their importance in your packaging and shipping operations will help you make the most of every palletizer demo you experience.

Whether you are watching a demo through an online video or in-person, here are some areas to examine:

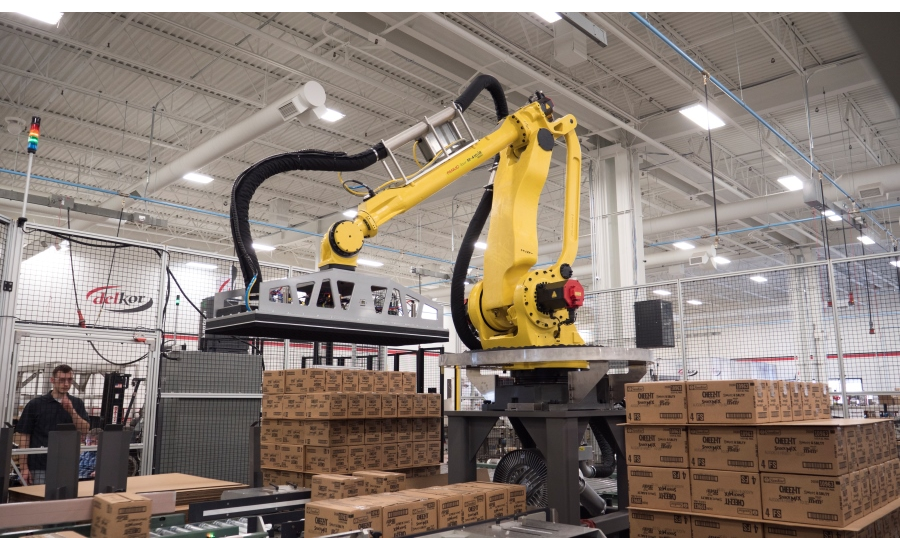

- For pick and place options, considering your load size, shape and weight is important. All of these factor into the ease of assembling your final pallet load. Robotic options for pick and place can streamline your operations and potentially increase ROI. In a demo, look for options that let you easily program different loads and provide bottom support for products.

- A load wrapping feature will provide more efficiency. In addition to consistency, automated load wrapping can reduce waste in pallet wrapping materials and provide a safe way to wrap even tall loads securely. For demos, look at the ability of the wrapping feature to adjust to a wide range of load dimensions.

- While we’re on the subject of wrapping, consider what happens if protective film breaks mid-process. With the right system, a film break doesn’t stop the process. When watching a palletizing demo, look for ways the system recovers in this scenario. If it’s not shown, ask about this time and headache saving feature.

- Pattern assembly is another area where automated or robotic palletizing has an edge over human assembly. A variety of conveyors and bars can ensure perfect alignment, leading to an increase in optimal packaging and efficient shipping. In a demo, look for the variety of options to move, square and align packages according to your prescribed pattern. Also consider what happens for defective patterns. Are they recognized and removed from the process?

- Finally, throughout any demo, look for safety features. A contained palletizing system should have a number of measures to eliminate any unsafe interaction with the system. Entry points should be controlled so that entry during processing is not possible. Emergency exits and maintenance access should also be features that are clearly demonstrated. The use of light curtains for more open areas of access will prevent unintended interactions with automated equipment, and redundant safety latches should require manual resetting if those features are engaged.

Online demos have the advantage of allowing you to replay them as often as needed to see every feature. In-person demos may follow a pre-determined script but give you the ability to ask questions and perhaps even see how systems can be reprogrammed to fit your needs. Maximizing the information you glean from a palletizer demo will be a great start to evaluating the best palletizing system and options for your packaging and shipping operations.