Precision machining has revolutionized the way industries operate. It involves creating intricate parts and components with extreme accuracy using advanced technology. This process has become a backbone for many sectors, providing essential tools and parts that are crucial for their operations.

Let’s explore how precision machining is making a significant impact across different industries.

Automotive Industry

The automotive industry relies heavily on precision machining. Components like engine parts, transmission systems, and brake components require high precision to ensure safety and performance. With precision CNC machining, manufacturers can produce parts that fit perfectly, reducing the risk of malfunction and improving the overall efficiency of vehicles.

This precision also allows for the creation of more fuel-efficient engines, contributing to environmental conservation.

Aerospace Industry

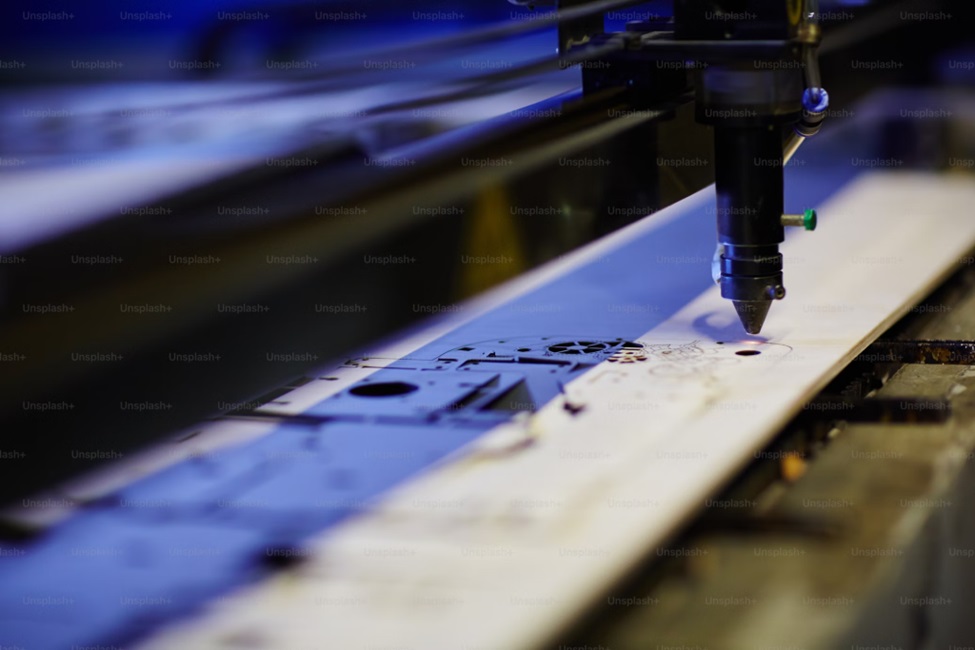

In the aerospace industry, there is no room for error. Aircraft parts must meet stringent standards for safety and performance. Precision machining enables the production of complex parts with tight tolerances, ensuring that each component functions perfectly under extreme conditions.

Techniques like laser cutting are used to achieve the high level of accuracy needed for parts such as turbine blades and structural components. This precision not only enhances the performance of aircraft but also ensures passenger safety.

Medical Industry

The medical industry benefits immensely from precision machining. Medical devices and implants, such as prosthetics, surgical instruments, and dental implants, require exact specifications to work effectively. Precision machining ensures that these devices are manufactured to the highest standards, improving patient outcomes and safety.

For instance, precision CNC machining is used to create custom-fit implants that are tailored to individual patients, enhancing the success rates of surgeries and treatments.

Electronics Industry

The electronics industry thrives on miniaturization and precision. Small, intricate components such as microchips, connectors, and sensors are essential for modern electronic devices. Precision machining allows manufacturers to produce these tiny parts with exact specifications, ensuring they work seamlessly in gadgets like smartphones, laptops, and medical equipment.

Energy Industry

The energy industry, particularly the renewable energy sector, benefits from precision machining in the production of wind turbine components, solar panel parts, and other energy-efficient systems. Precision machining ensures that these components are made to exact specifications, which enhances their efficiency and durability.

For example, precision cnc machining is used to create the gears and shafts in wind turbines, ensuring they operate smoothly and withstand harsh environmental conditions.

Manufacturing Industry

In general manufacturing, precision machining plays a vital role in producing high-quality products. From consumer goods to industrial machinery, the need for precision parts is universal. Techniques like precision machining enable manufacturers to create products with high accuracy and consistency.

This not only improves the quality of the final products but also reduces waste and increases production efficiency.

Conclusion

Precision machining is a cornerstone of modern industry, driving advancements and ensuring the production of high-quality, reliable components across various sectors. Its ability to create parts with extreme accuracy and consistency has transformed industries like automotive, aerospace, medical, electronics, energy, and manufacturing.

As technology continues to evolve, precision machining will undoubtedly play an even more critical role in shaping the future of these industries, fostering innovation and enhancing performance in countless applications.